HBI – DRI material transport, storage and dosing system for EAF. Continue reading “HBI – DRI storage and transport systems”

Author: Giulio Boni

With slag treatment systems

At the end of cast operation materials remained into the ladle are discharged in a vessel; after about three days, when materials have a temperature of about +300°C can be discharged above the vibrating grating. Continue reading “With slag treatment systems”

Belt conveyors and and Shuttle belt conveyors

Belt conveyors are used to carry or (with limited slope) to lift various bulk materials.

Continue reading “Belt conveyors and and Shuttle belt conveyors”

Weighing belt conveyors

Dosing belt conveyor, normally used for extraction material like ferroalloy, coal, lime, cement production, raw material and alumina from hoppers or bins.

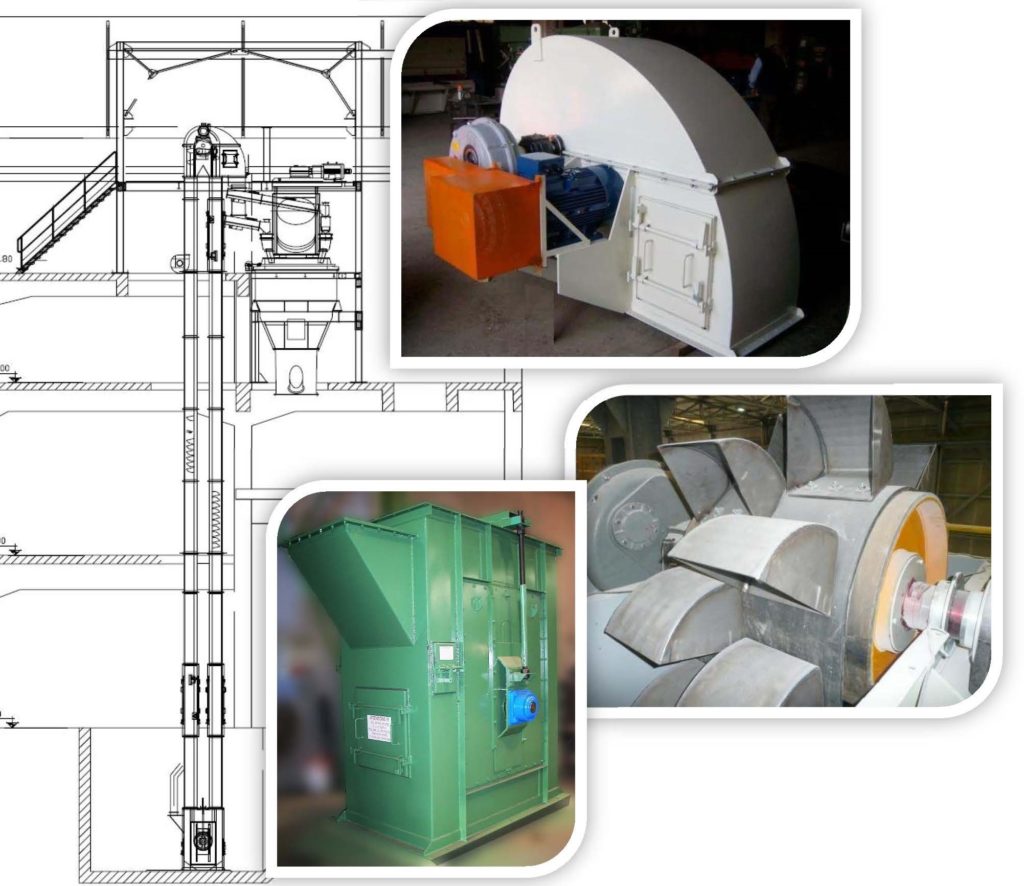

Bucket lifting conveyors

Bucket belt conveyors used to lift bulk materials in grains or powder. Max. grain size: 15 mm.

Base belt: hot galvanized steel cords for tension carrier and transverse reinforcement, with rubber cover. Bolted steel buckets.

Max. capacity up to 500 tonn./h

Head drive group comprise Gear Motor with apart slow emergency movement and idraulic coupler

Fast belt elevators, for conveyance of powdery and/or small-size materials.

Special characteristics include:

– Compact size

– Automatic belt centring

– Feed with minimum drag

– Special head with no recycled material

Special screw conveyors

Without intermediate supports, including exceptional length.

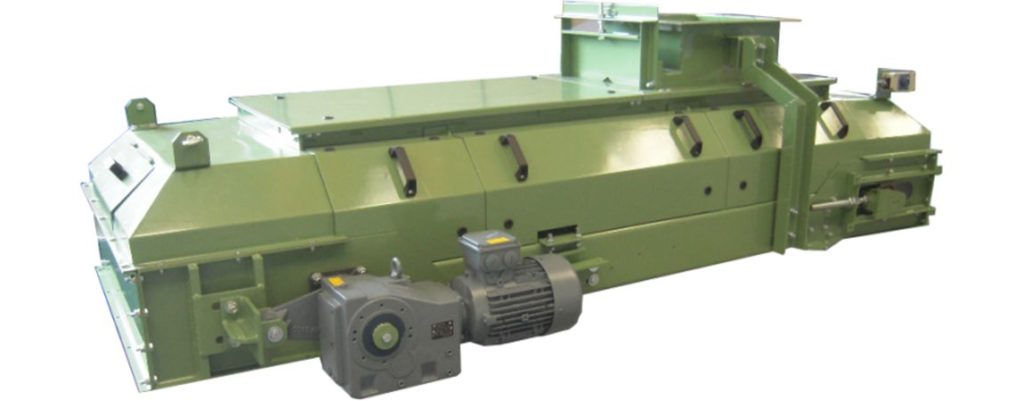

Chain conveyors

Chain conveyors for various kind of dusts. Continue reading “Chain conveyors”

2 and 3 way double cone buffer valve

Machinery designed to allow diversion and regulation of hot gas flow through mains converging into the valve itself. Continue reading “2 and 3 way double cone buffer valve”

Dust cover system

This type of material is used to cover liquid baths with silicon and carbon dust to reduce the heat dispersion. Continue reading “Dust cover system”

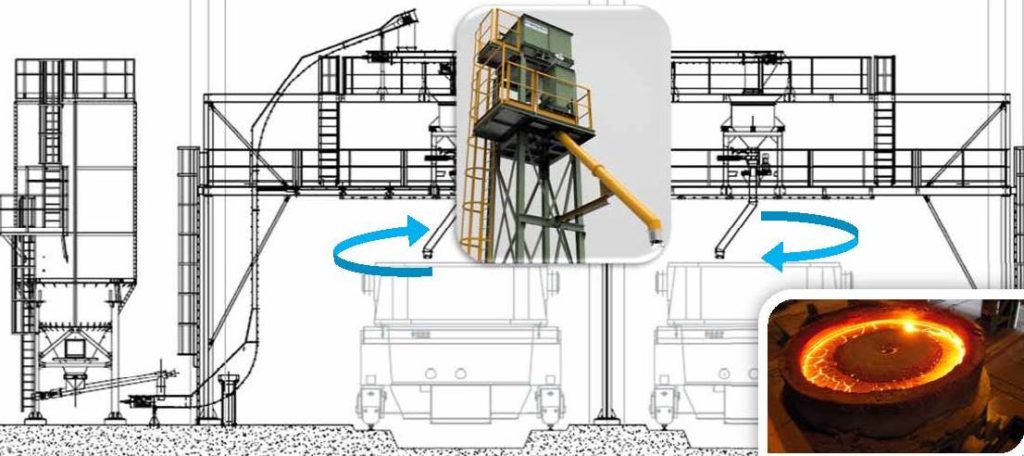

EBT hole filling system with rotating screw conveyor

EBT hole filling system with grain are used to add granular magnetite and silicon in the hole of the EBT. These systems are installed over the EAF platform and thanks to the rotating translation of the screw conveyor is possible to pour material in the EBT hole when the furnace stands in a pre – stabilized position. Continue reading “EBT hole filling system with rotating screw conveyor”